PitGrowth × Industry 4.0 Solutions

Transforming manufacturing and operations through smart technologies.

The old way

Smart Manufacturing

Implementation of connected machines, digital twins, and real-time monitoring enabling fully optimized production lines.

Industrial IoT (IIoT)

Deployment of sensors, edge devices, and connected systems to gather and process critical data across complex factory environments.

Robotics & Automation

Strategic implementation of collaborative robots (cobots), automated assembly systems, and specialized logistics robotics.

Artificial Intelligence & Machine Learning

Utilizing predictive maintenance, enhanced quality control, and sophisticated algorithms for deep process optimization.

3D Printing & Additive Manufacturing

Enabling on-demand production, rapid prototyping, and the creation of highly customized parts using advanced 3D printing technologies.

Explore More

Discover all solution categories in Industry 4.0 Solutions

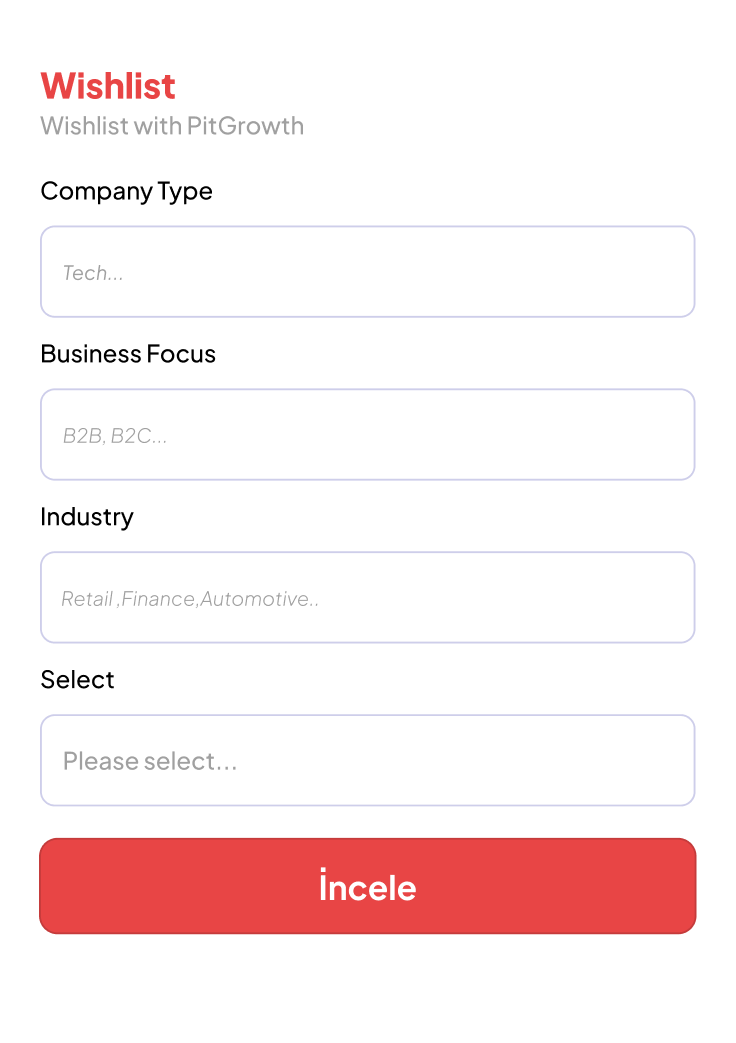

Find Right Partners

Our platform brings together solution providers in the industry 4.0 solutions field to help you establish reliable business partnerships.

Smart Matching

Automatically find solution providers that match your needs

Verified Providers

All solution providers go through identity and qualification verification

Direct Communication

Opportunity to communicate directly with technical experts and decision makers

Success Tracking

Monitor the performance of your solution implementations

Real-World Use Cases

Discover how leading companies leverage industry 4.0 solutions to drive business success

Enhancing Asset Uptime via Predictive Analytics

Deploying AI and IIoT sensors to monitor machine health in real-time, accurately predicting equipment failures before they cause operational downtime.

Key Benefit

25% reduction in unplanned downtime and substantial savings on spare parts inventory management.

Zero-Defect Production using Computer Vision

Integrating high-speed computer vision systems powered by ML models to automatically inspect products for defects and anomalies during rapid production cycles.

Key Benefit

Drastic reduction in defect rates (PPM) and verifiable enhancement of overall product quality and integrity.

How It Works

Find the right business partner and build strong connections in 4 simple steps.

Register

Add your company information and create your profile

Define Needs

Specify the criteria for the business partner you are looking for

Connect

Get in touch with suitable companies

Start Partnership

Make an agreement and start your partnership

Average Process Timeline

Time from registration to successful partnership

Frequently Asked Questions

Common questions about implementing industry 4.0 solutions solutions

How can corporations benefit from Industry 4.0 solutions?

Corporations achieve substantial benefits including improved operational efficiency, significant reduction in machine downtime, and accelerated innovation cycles. Industry 4.0 technologies fundamentally enhance global competitiveness and drive sustainability goals.

What’s the value for startups in the Industry 4.0 ecosystem?

Startups gain high visibility with major industrial players and investors actively seeking disruptive innovations. The platform accelerates technology adoption by facilitating validated pilot projects and strategic partnerships with corporate buyers.

Can Small and Medium Enterprises (SMEs) also benefit from Industry 4.0 adoption?

Absolutely. Modern, modular solutions in areas like Industrial IoT, cloud-based analytics, and scalable robotics allow SMEs to gradually adopt Industry 4.0 principles without requiring massive initial capital investment.

How are Industry 4.0 vendors verified?

Vendors undergo a rigorous vetting process based on comprehensive case studies, verified customer references, and assessment of relevant industrial certifications. Only providers demonstrating proven success in industrial-scale deployments are listed.

What Key Performance Indicators (KPIs) matter most in Industry 4.0 projects?

Critical metrics include downtime reduction, manufacturing throughput increase, reduction in defect rates, optimization of energy efficiency, and overall Return on Investment (ROI) measured across the lifecycle of the deployment.